Disinfection in medical environments is vital for preventing healthcare-associated infections (HAIs) and ensuring patient safety. Several methods are used for hospital room sanitation, each with unique benefits and limitations. Chemical disinfection, often applied via spray, is effective at covering large areas and reaching hidden surfaces. Disinfectants like hydrogen peroxide, hypochlorous acid, and alcohol-based solutions work by disrupting microbial cell membranes, offering broad-spectrum activity. Chemical disinfection is effective in areas not exposed to light, but it can leave residues and requires drying time. Additionally, strong chemicals may damage sensitive equipment and pose health risks if mishandled.

Fogging disinfection, using ultrafine droplets of disinfectant, provides comprehensive coverage and is highly effective in sterilizing both surface-bound and aerosolized microbes. However, it requires significant downtime for ventilation and incurs high operational costs due to specialized systems. Heat-based disinfection, such as autoclaving, effectively sterilizes medical instruments by using high temperatures to eliminate pathogens, but is not suitable for room-wide disinfection due to energy demands and equipment limitations. Gamma and electron beam irradiation offer advanced sterilization techniques for medical devices, but their application in hospital rooms is impractical due to the need for specialized equipment and radiation safety protocols.

UV-C light disinfection is a non-chemical method that uses ultraviolet radiation to inactivate pathogens by damaging their DNA and RNA. It is fast, effective against a broad range of microorganisms, and can be integrated into robotic systems for automated disinfection cycles. However, UV-C light’s effectiveness is reduced by shadowing, as it cannot penetrate opaque objects, and direct exposure can cause harm. Innovations in UV-C technology, such as far-UVC (222 nm), show promise for safer, more efficient disinfection. Combining UV-C light with air circulation systems can further enhance pathogen elimination, addressing both surface and airborne threats.

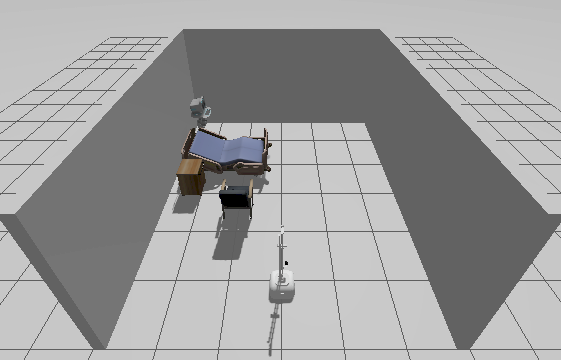

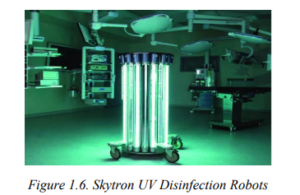

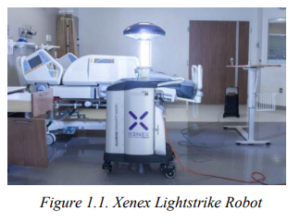

Automated solutions, including UV-C robots and mist-based systems, offer enhanced disinfection but have limitations:

- Xenex LightStrike: High efficacy but costly (~$125,000) and limited by shadowed areas.

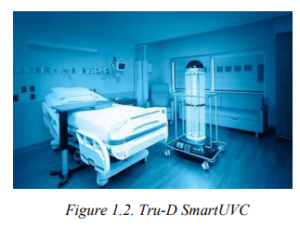

- Tru-D SmartUVC: Adjusts UV-C exposure time for thorough cleaning but is slow and expensive.

- UVD Robots: More affordable (~$67,000), autonomous, but still hindered by shadowing.

- Surfacide Helios: Multi-tower system minimizes shadowing but increases cost and complexity.

- Mist-Based HPV Systems: Effective whole-room coverage but requires extended downtime for ventilation.

After a thorough examination of various sanitization techniques, UV-C emerged as the most feasible option due to its rapid effectiveness and the advantage of requiring no downtime.Considering UV-C as the optimal sanitisation method, further research was conducted.

- Mechanism of UVC Sterilization

- UVC light (wavelengths between 200–280 nm) is highly effective at disrupting microbial DNA, preventing replication.

- The optimal germicidal wavelength is 265 nm, but commercial UVC devices commonly use 254 nm, as it is efficiently produced by low-pressure mercury lamps.

- UVC Sources for Sterilization

- Mercury-Based UVC Lamps

- Low-pressure mercury lamps: Emit ~254 nm; used in hospitals, water treatment, and air sterilization.

- Medium-pressure mercury lamps: Higher intensity, used for industrial-scale sterilization.

- LED-Based UVC

- Emit specific UVC wavelengths (e.g., 260–280 nm).

- More energy-efficient, durable, and mercury-free, but currently less powerful than mercury lamps.

- Excimer Lamps (Far-UVC, 222 nm)

- Emerging technology that may be safer for human exposure.

- Shown to effectively kill bacteria and viruses while minimizing harm to human skin and eyes.

While UV-C light is highly effective for disinfection, its operation requires specific electrical and structural components to function properly. Unlike simple LED systems, UV-C lamps require several key elements: 1.) Ballasts for Power Regulation: UV-C lamps, particularly low-pressure mercury vapour lamps, require a ballast to regulate current flow and ensure stable operation. Without a ballast, the lamp could overheat or fail to function correctly. 2.) AC Electricity Requirement: Many commercial UVC lamps operate on AC power rather than DC. This is because AC allows for more stable and efficient operation of gas-discharge lamps. Step-up transformers may be needed in some cases to achieve optimal UV-C output. 3.) Wavelength Considerations: The most effective UVC disinfection wavelength is around 254 nm, which is commonly emitted by mercury vapour lamps. LED-based UV-C is emerging, but its efficiency is still lower than traditional mercury lamps. 4.) Safety Mechanisms: UV-C exposure can cause skin burns and eye damage, requiring shielding and motion sensors to prevent accidental exposure. Timers and remote activation systems help ensure safe operation. 5.) Durability and Maintenance: UV-C lamps degrade over time and need periodic replacement. Dust accumulation can reduce effectiveness, necessitating regular cleaning.

The full literature review can be found here Literature review 1.docx

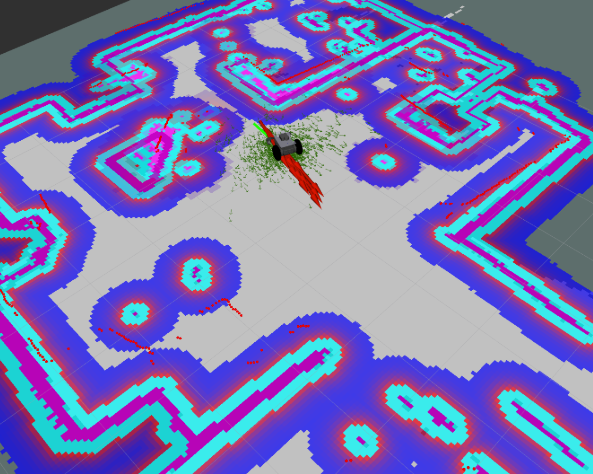

An investigation was also conducted into path planning.

Effective path planning maximizes surface coverage, minimizes redundant paths, conserves energy, and reduces operational time. However, using UV-C bulbs introduces constraints such as safety concerns, limited penetration, and exposure calibration.

Path Planning in Robotics Path planning ensures that robots navigate efficiently, avoiding obstacles while covering designated areas. Challenges specific to sanitization include dynamic environments, complete coverage requirements, time constraints, and safety concerns. Several path planning algorithms are used, including:

- A Algorithm:* Finds the shortest path using heuristics but struggles in dynamic settings.

- Dijkstra’s Algorithm: Guarantees shortest paths but is computationally intensive.

- Rapidly-exploring Random Trees (RRT): Efficient for complex environments but may not ensure optimal paths.

- Genetic Algorithms (GA): Optimize paths through evolutionary techniques.

- Simultaneous Localization and Mapping (SLAM): Enables robots to build and update maps in real time.

Unique Constraints for UV-C Sanitization Robots Several factors impact the effectiveness of UV-C sanitization:

- UV-C Light Properties: Limited penetration requires careful positioning.

- Distance & Intensity Requirements: Effective disinfection depends on proximity and exposure time.

- Field of View (FoV): Shadows and obstructions must be accounted for.

- Surface Geometry & Environmental Constraints: Complex surfaces necessitate adaptive strategies.

- Energy Efficiency: Optimized routes reduce energy consumption and prolong battery life.

Optimisation Problem Definition

Objective Function: Maximising Surface Coverage While Minimising Redundant Passes

The primary goal is to ensure comprehensive disinfection by maximising the surface area covered by the robot, while simultaneously reducing unnecessary overlaps in its path. This balance enhances efficiency and conserves energy.

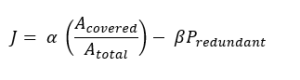

Let:

- Atotal represent the total area requiring disinfection.

- Acovered denote the area effectively covered by the robot.

- Predundant signify the length of paths where the robot’s disinfection overlaps.

The objective function J can be formulated as:

Here, α and β are weighting factors that prioritise coverage and redundancy minimisation, respectively.

Constraints: Distance, Angle of Exposure, Time per Area

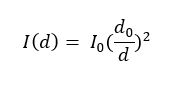

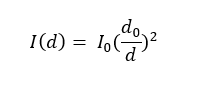

1. Distance Constraint: The efficacy of UV-C disinfection diminishes with increased distance from the source due to the inverse square law. If I0I_0I0 is the initial intensity at a reference distance d0, then the intensity I at distance d is:

To ensure effective disinfection, I(d) must remain above a threshold Imin.

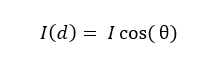

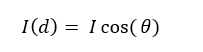

2. Angle of Exposure Constraint: The intensity of UV-C light also depends on the angle θ between the light source and the surface. The effective intensity Iθ is:

Surfaces must be oriented such cos(θ) remains sufficiently large to maintain Iθ ≥ Imin

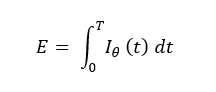

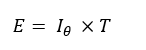

3. Time per Area Constraint: The disinfection dose D is a product of intensity and exposure time t

To achieve a required dose Dreq, the exposure time must satisfy:

These constraints ensure that each surface receives adequate exposure for effective disinfection.

Geometric and Kinematic Considerations

Robot Motion Modelling

Accurate modelling of the robot’s movement is crucial for precise path planning. Assuming a differential drive robot, its position (x,y) and orientation ϕ can be described by:

Here, v is the linear velocity, and ω is the angular velocity.

Path Curvature and Smoothness Constraints

To prevent mechanical strain and ensure consistent disinfection, the robot’s path should avoid sharp turns. The curvature κ of the path is given by:

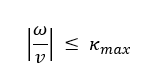

Imposing a maximum allowable curvature κmax:

This constraint ensures smooth and feasible trajectories.

Illumination Model

UV-C Intensity Function Over Distance

As previously discussed, UV-C intensity decreases with distance following the inverse square law:

Angle-Dependent Exposure Calculations

Considering the angle of incidence θ, the effective intensity on a surface is:

Formulation of Exposure Coverage as a Mathematical Function

The total exposure E a point on a surface receives is the integral of intensity over time:

For a constant intensity during exposure time TTT:

Ensuring E ≥ Dreq guarantees effective disinfection.

Modification of Existing Algorithms to Integrate UV-C Constraints

Traditional pathfinding algorithms like A* and Dijkstra’s are designed to find the shortest path between two points. However, for UV-C disinfection, it’s crucial to modify these algorithms to account for surface exposure requirements.

Adjusting A or Dijkstra’s for Surface Exposure

The standard A* algorithm uses heuristics to determine the shortest path. To adapt it for UV-C disinfection, the heuristic can be modified to consider factors such as the intensity and duration of UV-C exposure needed for effective disinfection. This ensures that the robot’s path not only covers all areas but also provides sufficient exposure time to deactivate microorganisms.

Similarly, Dijkstra’s algorithm, which finds the shortest path in a graph, can be extended to account for UV-C constraints. By incorporating surface exposure requirements into the algorithm’s cost function, the robot can plan paths that ensure comprehensive disinfection. For instance, an extended Dijkstra algorithm has been proposed that models the environment using Delaunay triangulation, allowing for smoother and more efficient paths on complex surfaces.

Hybrid Methods Incorporating Optimization Techniques

To enhance path planning, hybrid methods that combine traditional algorithms with optimization techniques like Particle Swarm Optimization (PSO) and Genetic Algorithms (GAs) can be employed. These methods optimize the robot’s trajectory by considering multiple factors, such as obstacle avoidance, energy consumption, and UV-C exposure levels.

For example, a study utilized bio-inspired algorithms to adjust a robot’s coordinates and stopping times at key points, ensuring complete disinfection coverage while minimizing the risk of excessive UV-C exposure. By integrating PSO or GAs with pathfinding algorithms, the robot can dynamically adapt its path to varying environments, achieving optimal disinfection efficiency.

5.2 Coverage Path Planning (CPP) Techniques

Coverage Path Planning focuses on creating paths that allow the robot to cover an entire area systematically, ensuring no spots are missed during disinfection.

Exact and Heuristic-Based Solutions

Exact methods aim to provide complete coverage with mathematically proven strategies. These methods often involve decomposing the area into smaller, manageable sections and planning paths that cover each section efficiently. However, exact methods can be computationally intensive, especially in complex environments.

Heuristic-based solutions, on the other hand, use rules of thumb or strategies that provide good enough coverage with less computational effort. While they may not guarantee complete coverage, they are often faster and more adaptable to dynamic environments.

Lawn-Mower Pattern vs. Spiral vs. Randomized Strategies

Several CPP strategies can be employed:

- Lawn-Mower Pattern: This method involves the robot moving back and forth in parallel lines, similar to mowing a lawn. It’s straightforward and ensures systematic coverage but may be inefficient in irregularly shaped areas.

- Spiral Pattern: The robot starts at a central point and moves outward in a spiral. This approach is effective in open areas and reduces the number of turns, which can save time.

- Randomized Strategies: The robot moves in random directions, which can be useful in complex environments with many obstacles. However, this method doesn’t guarantee complete coverage and may require more time.

Full literature review found here : Algorithmic Study.docx

February 4th, 2025 10:45 pm